Recycling in Italy 2023 Report has once again confirmed our country’s excellence when it comes to wood: with a recycling rate of 62.7%, which is equivalent to about 2.2 million tons, the target set by the European Union for 2030 for packaging waste, which is only 30%, has long since been overcome.

In the landscape of the wood industry, that of Saviola Group has been one of the leading names for many decades: 1.5 million tons of recycled wood and 6 million pieces of kit furniture made each year provides a measure not only of the company’s environmental impact, but also of its importance within the Italian recycling. This results in an even more important number: this production is considered to avoid the felling of 4 million trees.

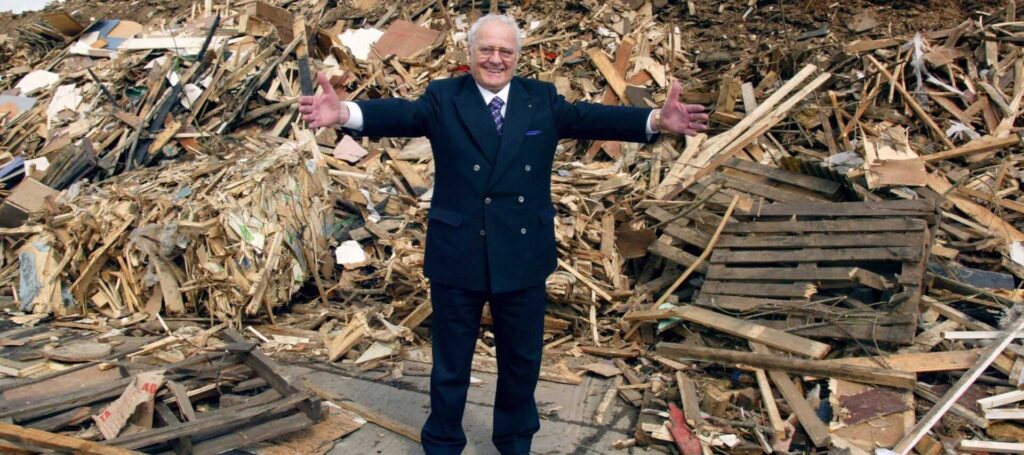

The origins can be dated back to 1963, when Mauro Saviola, together with his brother Angelo and Dino Del Ton, set the groundwork for what is now a company consisting of 15 plants spread across Italy, Europe and Argentina, employing about 2,000 people.

The company is based in Viadana, a town in Mantua, close to the Po River, which of course provides plentiful forest timber. In addition to this logistic advantage, Mauro Saviola adds a cutting-edge vision, understanding the importance of a permanent investment in R&D – an aspect that still characterizes the Group’s strategy.

When the concept of wood recycling was developed in the 1980s, the company operated according to a circular economy model, without this term still being used. Raw material is plentifully gathered from industrial processing waste and, years later, also from household trash.

Waste turns into value

Gearing up with new technologies and expanding its production facilities, Saviola Group is challenging the industry giants with a logic of integrated and sustainable production. The endeavor is not mundane, as the wood has to be cleaned of nails, paper, organic debris, and more, yet Mauro Saviola stands strong on the need to widely spread the recycling effort.

The entrepreneur glimpsed a future where eco-sustainability was not just an option, rather an unavoidable need: his dream of producing a 100% chipboard from recycled wood became true in the mid-1990s, when the Ecological Panel was launched on the market, produced exactly from materials formerly defined as waste, the first to be FSC Recycled 100% certified.

Keeping investing in research and acquiring companies specializing in specific processing, a milestone was crossed in 1997: 100% of production was made of ecological panels. In other words, from that moment on, all Saviola panels would be made without felling a tree.

The Mantuan entrepreneur’s far-sightedness to every aspect of the production chain characterizes every other company of the Group: Sadepan Chimica was born to produce low-formaldehyde glues, Composad has quickly become a leading name in kit furniture, especially for kitchens and offices. The Savionet division is responsible for the collection, sorting and cleaning of post-consumer wood through a network of 30 plat forms (known as “ecolegno”), distributed throughout Europe and also supplying materials to other companies interested in sustainable solutions; finally, Saviolife, the business unit dedicated to life sciences, bears witness to the relentless pursuit of new sustainable solutions in a range of sectors.

Benchmark for a worthy supply chain

When Rilegno, the national consortium for the collection, recovery and recycling of wood packaging, was founded in 1997, Saviola’s input was key toward the development of the system for collecting and recycling post-consumer wood: considering that 97 % of post-consumer wood is recycled by furniture and home decor industry into chipboard panels, the value of Mauro Savio’s insights and initiative can be well understood.

Mauro Saviola discovered recycling very early: he began working as young as 11, an apprentice joiner in the workshop of his father Alfredo, a cabinetmaker. As a young entrepreneur, Mauro began producing chipboard made from cottonwood processing waste, the material fruit crates are made of.

From the first machine purchased in Germany to crush the wood branches and press the chips, the company’s growth has kept going: his son, Alessandro Saviola, has taken the reins since 2009, carrying on the philosophy of TheEcoEthicalCompany, even gaining B Corp certification (among the largest in Italy to do so). Here is their Sustainability Report.

Currently, Saviola supplies companies such as Scavolini, Mondo Convenienza, Molteni, Ikea, and Leroy Merlin, to name the best-known brands; exports to 88 countries account for 40% of the reference market, a figure expected to grow in the future.

The philosophy of recycling and reusing wood keeps its roots deep, as the proven innovative approach: investments in Industry 4.0 are aimed at ensuring an increasingly efficient and eco-sustainable production process. Similarly, social responsibility still features in the company, through an ongoing relationship with staff, management rationality and a strong commitment to research and sustainability.

Saviola Group is thus an example of sustainability in the industrial framework, yet in terms of corporate governance as well: its story tells of an entrepreneurship driven by passion, innovation and a deep respect for the environment. The quality of its solutions, with the goals and results achieved, once again confirm how the circular economy approach can and should successfully apply.